12 2024

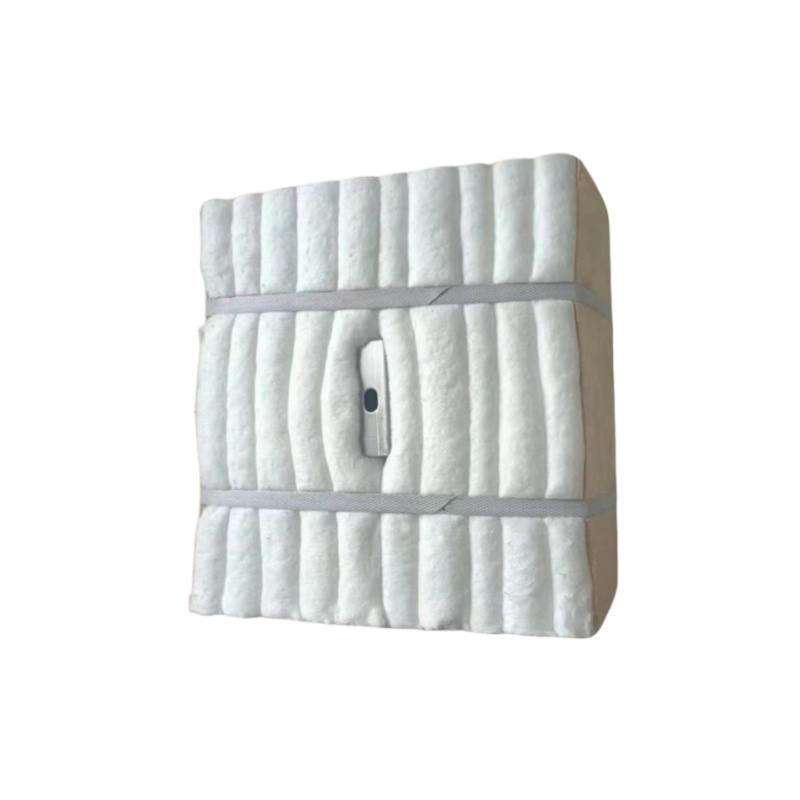

Refractory ceramic fiber modules are mainly made of high-purity ceramic fibers and related materials through high-temperature sintering or compression. Common refractory fiber materials include aluminosilicate fibers, calcium silicate fibers, etc. Fiber modules are usually prefabricated designs with metal hoops or special fixing devices. When installed, they can be directly laid tightly on the inner wall of high-temperature equipment or the surface of the furnace to ensure uniform insulation effect.

Main features:

Excellent high-temperature thermal insulation performance

Refractory ceramic fiber modules can withstand temperatures up to 1000°C or even higher, and can still maintain low thermal conductivity in extreme thermal environments to achieve good thermal insulation effects.

Lightweight and efficient

Compared with traditional refractory bricks and other thermal insulation materials, ceramic fiber modules are lighter in weight, which can reduce structural burdens, and have good thermal conductivity and thermal stability, which can effectively reduce energy consumption.

Strong thermal stability

Even in a high-temperature fluctuating environment, ceramic fiber modules still maintain excellent stability, high temperature resistance, strong thermal shock resistance, and are not easy to crack or damage under rapid temperature changes.

Quick installation and maintenance

Due to the modular design, the installation speed of refractory ceramic fiber modules is fast, and the on-site construction is simpler, saving a lot of labor and time costs. At the same time, the modules are easy to disassemble and replace, which is convenient for later maintenance and maintenance.

Resistant to chemical corrosion and high-temperature oxidation

Ceramic fiber modules have strong corrosion resistance to most acids, alkalis and organic chemicals, so they can be used for a long time in harsh environments.

Environmentally friendly and non-toxic

The raw materials used in high-quality refractory ceramic fiber modules meet environmental protection standards, and no harmful substances will be released during use, ensuring the safety of the use environment.

Main application areas:

Metallurgical industry

Used for insulation and heat preservation of furnace lining, it can effectively reduce heat loss and improve the temperature stability and production efficiency in the furnace.

Petrochemical industry

In petroleum refining and chemical reaction equipment, refractory ceramic fiber modules can ensure the high temperature resistance and heat insulation effect of the equipment, and improve the safety and energy efficiency of production.

Power industry

Applied in boilers, chimneys, heat exchangers and other equipment, refractory ceramic fiber modules effectively reduce energy consumption and improve the economy of equipment operation.

Ceramics and kilns

In the insulation of high-temperature equipment such as ceramic kilns and glass melting furnaces, ceramic fiber modules show excellent thermal isolation capabilities, improve production efficiency and reduce heat loss.

Aerospace and aviation

Due to its lightweight and high-temperature resistant characteristics, refractory ceramic fiber modules are also used in the aerospace field for protection and heat insulation.

Advantages:

Energy saving and consumption reduction: Excellent thermal insulation performance effectively reduces equipment heat loss, thereby saving energy and reducing operating costs.

Extend equipment service life: Good thermal stability and thermal shock resistance can effectively protect the inside of the equipment from high temperature and extend the service life of the equipment.

Improve production efficiency: Reduce equipment heat loss, maintain a constant temperature, and ensure the stability and efficiency of the production process.

Flexible adaptation: Refractory ceramic fiber modules can be customized according to actual needs and adapt to various shapes and sizes of equipment.

Summary:

Refractory ceramic fiber modules have become an indispensable and important material in the industrial field due to their excellent high-temperature thermal insulation performance, lightweight durability, and quick installation and maintenance. It can not only significantly improve the working efficiency of equipment, but also bring more significant energy-saving and consumption-reducing effects to enterprises. It is an ideal choice of insulation materials in modern high-temperature environments.

We focus on the research and development as well as manufacturing

of thermal insulation materials and sealing materials.