12 2024

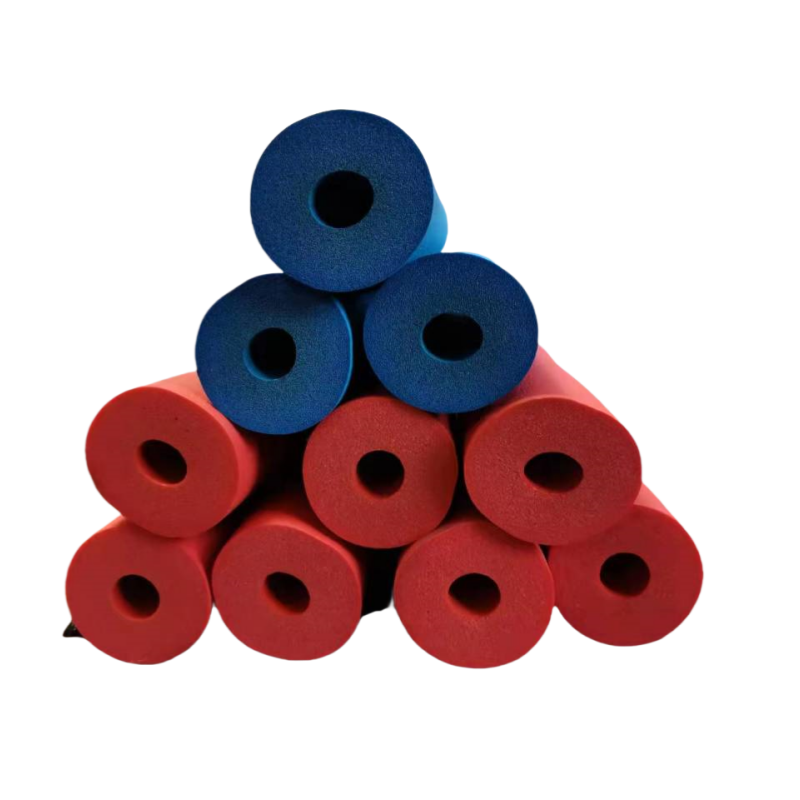

Rubber plastic sponge tubes are widely used in many industries such as construction, automobiles, homes and industry due to their lightness, durability and flexibility. In order to ensure their long-term use and optimal performance, regular maintenance and care are essential. This article will provide you with some practical maintenance and care tips to help you extend the service life of rubber plastic sponge tubes.

1. Regular inspection

Appearance inspection: Regularly inspect the appearance of the sponge tube for signs of cracks, wear or deformation. Any obvious damage should be dealt with promptly.

Connection: Check whether the connection is firm and ensure that there is no looseness or leakage.

2. Cleaning

Cleaning frequency: Clean the sponge tube regularly according to the use environment. It is generally recommended to clean it once a month or immediately after use in a highly polluted environment.

Cleaning method:

Use warm water and neutral detergent, avoid using strong acid or strong alkaline detergents.

Wipe gently with a soft cloth or sponge, and avoid using abrasive materials.

Rinse with clean water after cleaning to ensure that there is no detergent residue.

3. Storage

Storage environment: Store the rubber plastic sponge tube in a dry, cool place, avoid direct sunlight and high temperature environment to prevent material aging.

Avoid heavy pressure: Avoid heavy objects on the sponge tube during storage to prevent deformation.

4. Avoid chemical contact

Chemical influence: Avoid contact between the sponge tube and strong acids, strong alkalis or other corrosive chemicals, which may cause material degradation.

Pre-use inspection: Check the surrounding environment before use to ensure that there is no potential risk of chemical contact.

5. Temperature control

Temperature range: Rubber plastic sponge tubes usually have an applicable temperature range. Make sure to use it within this range to avoid the impact of high or low temperatures on the material.

Avoid extreme conditions: Try to avoid using the sponge tube at extreme temperatures, especially in high or low temperature environments.

6. Regular replacement

Service life: Regularly evaluate the service life of the sponge tube according to the frequency of use and environment. It is generally recommended to replace it every 1-2 years, depending on the use.

Replacement mark: If the sponge tube is found to be obviously worn, discolored or loses elasticity, replace it in time.

7. Professional maintenance

Seek professional help: When you encounter complex problems or are unsure how to deal with them, it is recommended to seek professional help to ensure the safety and performance of the sponge tube.

Conclusion

You can effectively extend the life of the rubber plastic sponge tube through regular inspection, cleaning, proper storage and avoidance of chemical contact. Follow the above maintenance and care guidelines to ensure that your sponge tube is always in the best condition and provide reliable support for your project.

We focus on the research and development as well as manufacturing

of thermal insulation materials and sealing materials.