-

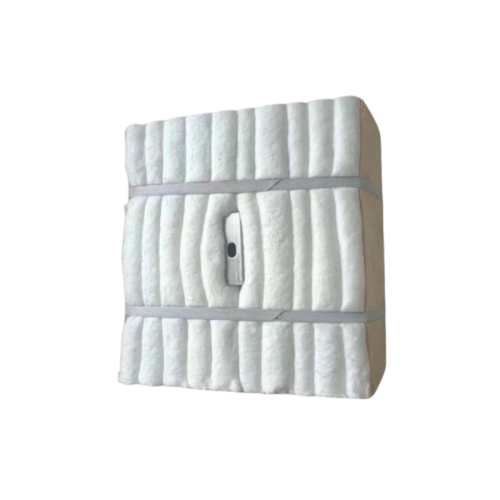

ceramic fiber module

Ceramic fiber modules have the following characteristics: Appearance - They usually have a regular block - like shape. The surface may be slightly textured, not as smooth as some other materials. The color is often off - white or light gray, giving a solid and reliable visual impression. Physical Properties - Outstanding High - Temperature Resistance: Ceramic fiber modules can endure extremely high temperatures. They can maintain their physical and chemical properties stably in high - temperature environments, generally capable of withstanding temperatures above 1000 °C. This is similar to a fearless "fire - resistant warrior" in the industrial field. - Good Thermal Insulation Performance: They have excellent heat - insulation capabilities. They can effectively block the transfer of heat, reducing heat loss. It's like a warm - keeping shield for high - temperature equipment or furnaces. - Lightweight and Easy to Install: Ceramic fiber modules are relatively light in weight, which is convenient for transportation and installation. Workers can easily assemble them on the required parts, saving time and labor costs. Applications - They are widely used in industrial furnaces, kilns, and high - temperature reaction vessels. For example, in a steel - making furnace, ceramic fiber modules are used as lining materials to protect the furnace body from high - temperature erosion and improve the energy - saving effect of the furnace.

Sizes

The specifications and dimensions of ceramic fiber modules usually vary according to different production requirements and application scenarios. Here are some common ones:

Length

– The length generally ranges from 300mm to 600mm. For example, some commonly used modules may have a length of 300mm to fit smaller – sized industrial equipment or a length of 600mm for larger furnaces to reduce the number of installation pieces and improve installation efficiency.

Width

– The width usually varies from 200mm to 400mm. This range allows for flexibility in installation to adapt to different curvatures and shapes of the inner walls of furnaces or other high – temperature containers.

Thickness

– The thickness can be customized within a certain range, usually from 100mm to 300mm. A thicker module provides better heat insulation performance, while a thinner one may be used in applications where space is limited but some heat insulation is still required.