04 2025

Abstract: The group standard T/CBMF 191-2022 “Non-formaldehyde Glass Wool Products for Sound Absorption and Heat Insulation” formulated by the China Building Materials Federation has been released and will be implemented from November 15, 2022. In order to facilitate the understanding of the specific meaning of the standard terms and correctly implement the specific requirements and regulations of the standard, this paper introduces the background and significance of the standard preparation, and interprets its main terms to provide reference for the implementation and application of the standard.

Keywords: Non-formaldehyde Glass Wool, Sound Absorption, Heat Insulation

Non-formaldehyde glass wool products for sound absorption and thermal insulation are made of glass wool products with sound absorption and thermal insulation functions by using a binder that does not contain formaldehyde. Because this glass wool solves the problem of releasing harmful substances from traditional glass wool products at the source, it not only improves the working environment of glass wool production enterprises, but also protects the health of end users. It is completely in line with the development direction of green building materials. Formaldehyde-free glass wool products are the mainstream products of glass wool products in developed countries in Europe, America and other countries. The product is still in its infancy in domestic construction and engineering applications, but as a new type of green building material, formaldehyde-free glass wool products are increasingly favored by designers, favored and affirmed by industry experts, and have broad application prospects.

1. Background and significance of standard preparation

At present, the domestic standards for glass wool products include: GB/T 13350-2017 “Glass wool for thermal insulation and its products”, GB/T 17795-2019 “Glass wool products for architectural thermal insulation” and JC/T 469-2014 “Glass wool products for sound absorption” [1~ 3]. GB/T 13350-2017 “Glass wool for thermal insulation and its products” applies to glass wool products for thermal insulation, focusing on thermal insulation performance and high temperature performance technical indicators; GB/T 17795-2019 “Glass wool products for thermal insulation in buildings” applies to glass wool products for thermal insulation and ventilation ducts for buildings, and sets relevant technical indicators for the application of glass and cotton in the field of construction engineering; JC/T 469-2014 “Glass wool products for sound absorption” applies to glass wool products for sound absorption, focusing on the sound absorption and noise reduction performance of glass wool felt and board. As a sound-absorbing material for building insulation, glass wool products have inseparable sound absorption and thermal insulation properties. There is a lack of standards to unify the sound absorption and thermal insulation properties of glass wool. In order to standardize the rational application of formaldehyde-free glass wool products for sound absorption and thermal insulation in construction projects, improve the quality level of glass wool products, and play a leading and normative role in standards, the China Building Materials Federation has issued formaldehyde-free, glass wool products standard devise plans, which are formulated by the joint stock company of Beijing Building Materials Inspection and Research Institute. Therefore, the preparation team has carried out a large number of standard investigations, verification tests, and application studies, etc. At present, T/CBMF 191-2022 “formaldehyde-free glass and cotton products for sound absorption and heat insulation” has been released and will be implemented from November 15, 2022.

2 The main content and basis for the preparation of standards

T/CBMF 191-2022 is drafted in accordance with the rules given by GB/T 1.1-2020 and follows the following rules: the principle of implementing national policies and regulations and harmonizing with other current national standards; the principle of advanced, feasible and reasonable technical indicators; the principle of highlighting product characteristics and promoting the healthy development of the industry and product promotion. During the standard formulation process, refer to GB/T 17795-2019 “Thermal Insulation for Buildings”For the relevant content in “Glass Wool Products”, GB/T 13350-2017 “Glass Wool for Thermal Insulation and Its Products” and JC/T 469-2014 “Glass Wool Products for Sound Absorption”, the test methods should refer to the current national standards and industry standards as much as possible.

2.1 Terms and definitions

This standard specifies the specific definitions of the terms formaldehyde-free products and formaldehyde-free adhesives for sound absorption and thermal insulation.

Non-formaldehyde glass wool products for sound absorption and heat insulation are made of formaldehyde-free adhesives and adhesives to make glass wool products with sound absorption and heat insulation functions, including formaldehyde-free glass wool felt, formaldehyde-free glass wool board and formaldehyde-free glass cotton strips.

Formaldehyde-free adhesives are adhesives that do not use formaldehyde and the substances that decompose to produce formaldehyde as direct raw materials.

2.2 General requirements

Formaldehyde-free glass wool products are used in the field of construction engineering, and have strict requirements on the moisture content, hydrophobicity, and combustion performance of materials. Therefore, the slag ball content, moisture content, hydrophobicity, mass moisture absorption, and combustion performance grades are listed as general requirements. The specific index values are shown in Table 1. The index values of T/CBMF 191-2022 and GB/T 17795-2019 are consistent.

2.3 Environmental requirements

Environmental protection requirements refer to the impact of harmful substances in materials on the environment, including formaldehyde emission, volatile organic compounds (TVOC) emission, odor grade 3 indicators. The specific formaldehyde emission and T VOC emission, the index value is shown in Table 2. The formaldehyde-free glass wool products use formaldehyde-free binders in the production process to ensure that the products do not add formaldehyde in the production process from the source. After discussion and verification of the test results by the preparation group, the formaldehyde emission index is strictly set to not be detected, and the T VOC emission is set to ≤ 0.50mg/(m2 · h). The formaldehyde emission was carried out according to the 1m3 climate box method stipulated in GB/T 32379-2015 “Determination of formaldehyde emission from mineral wool and its products”; the T VOC emission was carried out according to GB/T29899The provisions of “Test method for release of volatile organic compounds in wood-based panels and their products, Small release chamber method” shall be carried out.

Table 1 Indicator requirements for relevant standards in the general requirementsTechnical indicators

| GB/T 17795-2019 | GB/T 13350-2017 | T/CBMF 191-2022 | |

| Slag ball content (particle size > 0.25mm),% | ≤0.3 | ≤0.3 | ≤ 0.3 |

| Moisture content,% | ≤1.0 | ≤1.0 | ≤ 1.0 |

| Hydrophobicity rate, % | ≥98.0 | ≥ 98.0 (waterproof performance) | ≥ 98.0 |

| Mass moisture absorption,% | ≤5.0 | ≤ 5.0 (waterproof performance) | ≤ 5.0 |

|

combustion performance class |

The combustion performance of glass wool products without outer coating shall not be lower than the A (A2) level of GB 8624-2012; products with outer coating

Combustion performance is negotiated by both supply and demand parties |

Should reach the nominal GB 8624-

The level stipulated in 2012 is not low At A (A2) level |

The combustion performance of formaldehyde-free glass wool products for sound absorption and thermal insulation without outer covering shall not be lower than grade A (A2) of GB 8624-2012; for formaldehyde-free glass wool products for sound absorption and thermal insulation with outer covering, the combustion performance shall be negotiated by both the supplier and the demander. |

Table 2 Indicator requirements of relevant standards in environmental protection requirements

| 技术指标 | GB/T

17795-2019 |

GB/T

13350-2017 |

T/CBMF 191-2022 |

| Formaldehyde emission, mg/m3 | ≤0.02 | must not be detected | must not be detected |

| TVOC release, mg/(m2 · h) | ≤0.50 | —— | ≤0.50 |

| Odor grade | ≤2

|

The odor level is a new technical indicator set by T/CBMF 191-2022. On the one hand, the safety and environmental protection of materials is whether their chemical content or release amount reaches a level that is harmful to health. On the other hand, their odor is also the main means of evaluating whether it will stimulate people’s sense of smell [4]. At present, in many fields such as interior decoration materials, textiles, food, contact materials, automotive interior materials, etc., the introduction of odor evaluation methods to control the environmental protection level of materials has become a common practice, and the relevant standard system is also relatively mature. The operation methods of these standards are similar, and the odor level of materials is evaluated by olfactory grading, but the details such as temperature and load capacity are different. The relevant standard detection methods are summarized in Table 3. Taking into account the production of glass wool and the use of adhesives in the process, from the perspective of material correlation, etc., the T/CBMF 191-2022 odor detection method is evaluated by referring to the odor assessment in Appendix J of GB 36246-2018 “Synthetic Material Surface Sports Field for Primary and Secondary Schools”, and the odor level should not be greater than 2 through verification tests.

2.4 Allowable deviation of size and density

For the allowable deviation of the size and density of formaldehyde-free glass wool felt, board and strip, the specific index values are shown in Table 4, Table 5 and Table 6. In order to improve the thermal insulation and sound absorption properties of formaldehyde-free glass wool, board and strip products, T/CBMF 191-2022 stipulates: the nominal density setting value of felt is ≥ 12kg/m3; the nominal density of board is strictly set to ≥ 32kg/m3, and the nominal density of strip is strictly set to ≥ 48kg/m3. Other indicators are consistent with the indicators of GB/T 17795-2019, and the specified values are consistent.

2.5 Thermal conductivity

The specific thermal conductivity of formaldehyde-free glass wool felt, board and strip

Table 3 Relevant criteria for odor evaluation

|

standard |

HG/T4065- 2008 Adhesive gas Taste evaluation method |

Determination of odor of leather QB/T2725-2005 |

SN/T 3179-

2012 Food Contact Material testing methods, paper And cardboard sensory analysis smell |

GB18401- 2010

National basic safety technical specification for textile products |

GB36246-2018

Primary and secondary school synthetic materials Surface sports venue |

ASTM C1304-2008

Standard Test Method for Assessing the Odor Emission of Thermal Insulation Materials |

| Material type | adhesive | leather | paper | Textile | synthetic material | thermal insulation material |

| detection method |

Closed tank odor classification method

|

Closed tank odor classification method |

Closed tank odor classification method

|

Direct olfactory discrimination | Closed tank odor classification method | Closed tank odor classification method |

| airtight tank | 1L glass jar | 1L metal or glass jar | 0.5L flat bottom flask | 1L odorless test bottle | Stainless steel or glass capacity

Device, sample volume 2.5 to 3 times |

|

| sample size | 20±1g | 125mm×100mm | 6dm2 | 20Mm × 50mm × actual thickness | No less than 57 grams. | |

| balance condition | Temperature: (23±2)℃. Place for 24 hours. | Place it for 24 hours at a temperature of (23±2)℃ and a humidity of (50±5)%. | Dark place, temperature. Place at (23±2)℃ for 20 to 24 hours. | 60℃,2h | 65℃,30min | |

| Test conditions | room temperature | room temperature | room temperature | room temperature | room temperature | |

| Test time | Test directly after opening. | 0.5h | ||||

| test population | At least three people | At least six people | 2 people test independently | no less than fiveno less than five people. | ||

|

detection result |

Level 5 (1 – no odor; 2 – slight odor that can be faintly sensed; 3 – there is an odor but without strong discomfort; 4 – strong uncomfortable odor; 5 – irritating and uncomfortable odor) | Level 5 (1 – No noticeable odor; 2 – Slight odor, but not noticeable; 3 – Obvious odor, but not unpleasant; 4 – Strong, unpleasant odor; 5 – Very strong unpleasant odor) | Level 5 (0 – no perceptible odor; 1 – odor just perceptible; 2 – moderate odor; 3 – moderately strong odor; 4 – strong odor) | No peculiar smell/Have peculiar smell and record the category of peculiar smell; (a) musty smell; (b) high boiling range petroleum smell; (c) fishy smell; (d) aromatic hydrocarbon smell; (e) fragrant smell. | Level 5 (1 – no odor; 2 – slight odor that can be felt faintly; 3 – odor present but without strong discomfort; 4 – strong discomforting odor; 5 – irritating and discomforting odor) | Pass/Fail (Whether it is a perceptible odor; the odor is unpleasant/comfortable/other; the odor is strong/weak) |

The index values are shown in Table 7. After comprehensively comparing the technical index values set by each standard in the table and considering the actual detection situation of the thermal conductivity coefficient, through the discussion of the compilation group and the verification test results, the thermal conductivity coefficient of formaldehyde-free glass wool mats, boards and strips is consistent with the index specified value of GB/T 17795-2019.

Table 4 Indicators and requirements of relevant standards for allowable deviations in size and density of formaldehyde-free glass wool mats

| technical indicators | GB/T

17795-2019 |

GB/T 13350 -2017 | T/CBMF 191-2022 | |

| Nominal density, kg/m3 | ≥12 | ≥10 | ≥12 | |

|

Size, density and allowable deviation. |

length mm | Not allowed negative deviation. | +10 No negative deviation is allowed. | No negative deviation is allowed. |

| width mm | +10 -3 | +10 -3 | +10 -3 | |

| thickness mm | No negative deviation is allowed. | No negative deviation is allowed. | Not allowed negative deviation. | |

| Nominal density, kg/m3 | +20% -10% | +20% -10% | +20% -10% | |

Table 5 Index requirements of relevant standards for allowable deviations in size and density of formaldehyde-free glass wool board

| technical indicators | GB/T

17795-2019 |

GB/T

13350-2017 |

T/CBMF 191-2022 | |

| nominal density, kg/m3 | ≥24 | ≥24 | ≥32 | |

|

Size, density and allowable deviation |

Length, mm | +10 -3 | +10 -3 | +10 -3 |

| Width, mm | +5 -3 | +5 -3 | +10 -3 | |

| Thickness, mm. 24≤ρ<32 | +5 0 | +5 0 | +5 0 | |

| Thickness, mm 32≤ρ≤64 | +3 -2 | +3 -2 | +3 -2 | |

| Thickness, mm ρ>64 | ±2 | ±2 | ±2 | |

| Nominal density, kg/m3 | +10% -5% | +10% -5% | +4% ~+9% -4% ~-8% | |

Table 6 Index requirements of relevant standards for allowable deviations in size and density of formaldehyde-free glass wool strips

| technical indicators | GB/T 17795- 2019 | GB/T 13350 -2017 | T/CBMF 191-2022 | |

| Nominal density, kg/m3 | ≥32 | ≥32 | ≥48 | |

|

Size and density allowable deviation |

Length, mm | ±10 | ±10 | ±10 |

| Width, mm | +3 -2 | +3 -2 | +3 -2 | |

| Thickness, mm | +4 -2 | +4 -2 | +4 -2 | |

| Nominal density, kg/m3 | ±10% | ±10% | ±10% | |

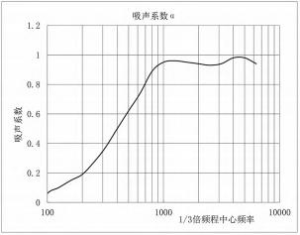

2.6 Sound absorption performance

Formaldehyde-free glass wool mat、The specific index values of the board’s noise reduction coefficient can be found in Tables 8 and 9. After discussions by the compilation team and verification test results, the specified index values of T/CBMF 191-2022 are kept consistent with those of JC/T 469-2014. Starting from the actual application situation of products, the nominal density of glass wool mats is increased by 12 kg/m3 and 20-40 kg/m3. The noise reduction coefficient value of the nominal density of 20-40 kg/m3 is the same as that of the nominal density of 24 kg/m3. The sound absorption performance of glass wool products is greatly related to the density and thickness of glass wool: (1) As the thickness increases, the mid-low frequency sound absorption coefficient significantly increases, but the high-frequency sound absorption coefficient changes little (the high-frequency sound absorption coefficient is a relatively high value); (2) With constant thickness and increased density, the mid-low frequency sound absorption coefficient also increases. Since glass wool strips are used by turning glass wool by 90°, the purpose is to increase the compressive strength value. Therefore, sound absorption performance is not listed as a performance index of glass wool strip products.

The noise reduction coefficient is carried out in accordance with the provisions of GB/T 18696.2 “Acoustics – Measurement of sound absorption coefficient and acoustic impedance in impedance tubes – Part 2: Transfer function method” or GB/T 20247 “Acoustics – Measurement of sound absorption in reverberation rooms”. GB/T 20247 is the arbitration test method. The test results of the sound absorption performance of formaldehyde-free glass wool felt with a nominal density of 24 kg/m3 and a thickness of 100 mm are shown in Figure 1.

Table 7 Index requirements of relevant standards for thermal conductivity of formaldehyde-free glass wool felt (thermal conductivity/[W/(m·K)])

| form | Nominal density (ρ)/(kg/m3) | GB/T 17795-2019. The average test temperature is (25±2)℃. | GB/T 13350-2017

Average test temperature: (25±1)℃ |

T/CBMF 191-2022

Average test temperature (25±2)℃ |

|

felt |

12≤ρ≤16 | ≤0.045 | ≤0.045 | ≤0.045 |

| 16<ρ≤24 | ≤0.041 | ≤0.041 | ≤0.041 | |

| 24<ρ≤32 | ≤0.038 | ≤0.038 | ≤0.038 | |

| 32<ρ≤40 | ≤0.036 | ≤0.036 | ≤0.036 | |

| ρ>40 | ≤0.034 | ≤0.034 | ≤0.034 | |

|

board / plank / plate |

32≤ρ≤40 | ≤ 0.040 | ≤ 0.036 | ≤ 0.040 |

| 40<ρ≤48 | ≤ 0.037 | ≤ 0.034 | ≤ 0.037 | |

| 48<ρ≤64 | ≤ 0.034 | ≤ 0.034 | ||

| ρ>64 | ≤ 0.035 | ≤ 0.035 | ||

| strip | ρ≥48 | ≤ 0.048 | ≤ 0.048 | ≤ 0.048 |

As shown.

2.7 Other requirements

Other requirements are optional technical indicators, including corrosion to metals and mildew resistance. The corrosion to metals is for metal-faced glass wool sandwich panels for buildings. The mildew resistance is for glass wool products for ventilation ducts. The indicator specified values of T/CBMF 191-2022 are consistent with those of GB/T 17795-2019. The specific indicator values are shown in Table 10. Four groups of formaldehyde-free glass wool products were selected for mildew resistance testing. Two groups of samples did not meet the standard requirements. The pass rate is 50%. The test results are shown in Figure 2.

Table 8 Index requirements of relevant standards for noise reduction coefficient (reverberation method)

| 形态 | T/CBMF 191-2022 | JC/T 469-2014 | ||||

|

felt |

Nominal density /(kg/m3) | Thickness/mm | Noise Reduction Coefficient (NRC) | Nominal density /(kg/m3) | Thickness/mm | Noise Reduction Coefficient (NRC) |

| 12 | 50 | ≥0.60 | ||||

| 75,100,150 | ≥0.80 | |||||

| 16~20 | 40,50 | ≥0.60 | 16

20 |

25 | ≥0.40 | |

| 40,50 | ≥0.60 | |||||

| 75,100 | ≥0.80 | 75,100 | ≥0.80 | |||

| 24~40 | 25,40 | ≥0.60 | 24 | 25,40 | ≥0.60 | |

| 50,75,100 | ≥0.80 | 50,75,100 | ≥0.80 | |||

|

board |

32~40 | 25,40 | ≥0.60 | 32

40 |

25,40 | ≥0.60 |

| 50,75,100 | ≥0.80 | 50,75,100 | ≥0.80 | |||

|

48~96 |

20,25 | ≥0.60 | 48

64 80 96 |

20,25 | ≥0.60 | |

| 40,50 |

≥0.80 |

40,50 |

≥0.80 |

|||

Note: For the reverberation chamber method, installation condition of the sample: rigid wall.

Table 9 Index requirements of relevant standards for noise reduction coefficient (impedance tube method)

| form | T/CBMF 191-2022 | JC/T 469-2014 | ||||

|

felt |

Nominal density /(kg/m3) | Thickness/mm | Noise Reduction Coefficient (NRC) | Nominal density /(kg/m3) | Thickness/mm | Noise Reduction Coefficient (NRC) |

| 12 | 50 | ≥0.30 | ||||

| 75 | ≥0.40 | |||||

| 100,150 | ≥0.60 | |||||

|

16 |

40,50 | ≥0.40 |

16 |

25 | ≥0.35 | |

| 40,50 | ≥0.40 | |||||

| 75 | ≥0.60 | 75 | ≥0.60 | |||

| 100 | ≥0.80 | 100 | ≥0.80 | |||

|

20 |

40 | ≥0.40 |

20 |

25 | ≥0.35 | |

| 40 | ≥0.40 | |||||

| 50,75 | ≥0.60 | 50,75 | ≥0.60 | |||

| 100 | ≥0.80 | 100 | ≥0.80 | |||

| 24~40 | 25 | ≥0.40 | 24 | 25 | ≥0.40 | |

| 40,50 | ≥0.60 | 40,50 | ≥0.60 | |||

| 75,100 | ≥0.80 | 75,100 | ≥0.80 | |||

| board / plate / plank | 32~40 | 25,40 | ≥0.60 | 32

40 |

25,40 | ≥0.60 |

| 50,75,100 | ≥0.80 | 50,75,100 | ≥0.80 | |||

|

48~96 |

20,25,40 | ≥0.60 | 48

64 80 96 |

20,25,40 | ≥0.60 | |

| 50 | ≥0.80 | 50 | ≥0.80 | |||

Note: Test specimen installation conditions: the felt is a rigid wall, and the plate has a rear cavity of 50 mm.

Table 10 Index requirements of other relevant standards for requirements

| technical indicators | GB/T 17795-2019 | GB/T 13350-2017 | T/CBMF 191-2022 |

|

Corrosiveness to metals |

When used to cover austenitic stainless steel, it should meet the stress corrosion requirements of GB/T17393.

When used to cover aluminum and steel, the rank sum test method with 90% confidence is adopted, and the rank sum of the control should not be less than 21. |

When used to cover austenitic stainless steel, it should meet the requirements of GB/T 17393. When used to cover aluminum, copper, and steel, the rank sum test method with a 90% confidence level is adopted, and the rank sum of the control should not be less than 21. | When used to cover austenitic stainless steel, it should meet the stress corrosion requirements of GB/T17393.

When used to cover aluminum and steel, the rank sum test method with 90% confidence is adopted, and the rank sum of the control should not be less than 21. |

| anti-mold performance | The result should not be lower than the level 1 result specified in Appendix B. | —— | Should not be lower than level 1 as specified in GB/T 17795-2019. |

Figure 2 Test results of mold resistance of formaldehyde-free glass wool products

Figure 1 Test results of sound absorption performance of formaldehyde-free glass wool felt with nominal density of 24kg/m3 and thickness of 100mm.

3 Conclusion

andGB/T 17795-2019《Glass wool products for building thermal insulation》、GB/T 13350-2017《Glass wool and its products for thermal insulation》and JC/T 469-2014《Glass wool products for sound absorption》相比,T/CBMF 191-2022《Formaldehyde-free glass wool products for sound absorption and thermalinsulation》The odor grade evaluation index was proposed for the first time, highlighting the environmental protection performance of formaldehyde-free glass wool. Technical indicators such as formaldehyde emission and nominal density of board and strip products were set strictly, which is conducive to improving the overall performance of formaldehyde-free glass wool products. According to the actual application situation of products, the sound absorption performance indicators of formaldehyde-free glass wool felt products with nominal density of 12 kg/m3 and 24-40 kg/m3 were added, and the formaldehyde-free glass wool felt products with nominal density of 16-20 kg/m3 and thickness of 25 mm were removed, providing users with multiple product choices. The official release and promotion of this standard will promote the high-quality development of new segmented glass wool products and provide a quality control basis for market application.

We focus on the research and development as well as manufacturing

of thermal insulation materials and sealing materials.